We design and manufacture hydraulic, pneumatic and mechanical machining jigs for our own production purposes as well as for sales to our customers.

We design and manufacture hydraulic, pneumatic and mechanical machining jigs for our own production purposes as well as for sales to our customers.

We design and manufacture various types of measuring and checking devices (position, shape, tightness checking, …) for the direct use during the production or positioning when measured by an automatic measuring system.

We use automation not only to increase the productivity and stabilize machining processes, but also for checking and complementary activities. We currently have 6 robots implemented.

We have installed a palletizing system of our own design and production to a 3-axis vertical center. Therefore, part replacement takes place in overlapping time and saves a considerable amount of capacities. We currently have two palletizing systems in operation.

To simplify the dispensing proces of measuring instruments, we have designed and developed an automated dispenser. Upon signing in with the RFID chip, employees borrow the gauges they need for the process. The box shows who currently has the gauge and at what workstation. The box checks the gauge calibration times and sends an email report. If a meter has passed calibration time, it does not allow the operator to use it.

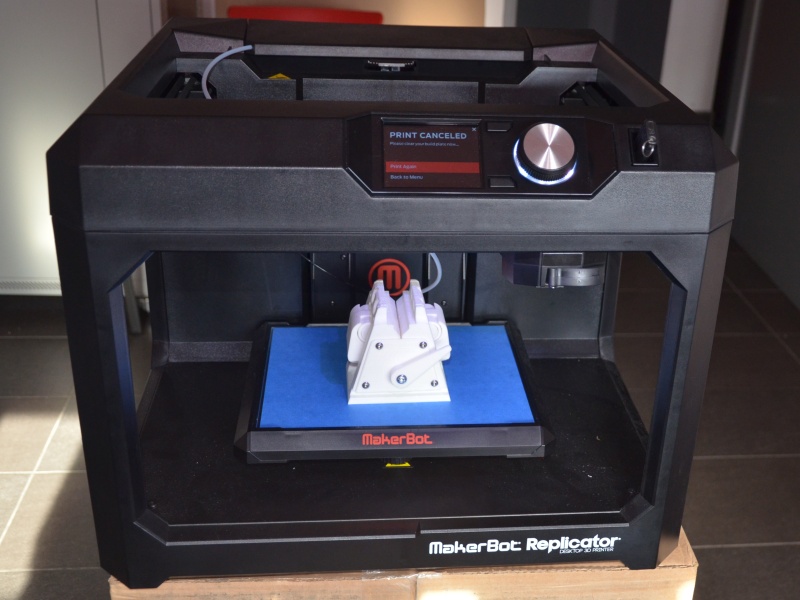

We have 3D printing technology used to make samples, models, clamping components, measuring devices.

Due to the relatively large machine fleet, we were facing the difficult question of how to monitor the use of their capacity. Only with this kind of information is it possible to better optimize production, ensure maximum utilization of machinery and an effective use of company time.

For this reason, we invested in the development of new software, called CNC Control SPY 0.6, working on the principle of monitoring the change in energy consumption of individual machines over time. CNC Control SPY 0.6 allows you to monitor the on-line situation during operation on a well arranged graphical chart, and using it you can create statistics on the use of working hours, machine utilization, production demands of the workpiece, and so on.

After the introduction of the CNC Control SPY 0.6 software, critical weak points of the production were revealed and remedial actions were taken immediately. In a short amount of time, the new software justified itself not just by optimizing production, but other companies working in similar fields showed their interest in use of the operator´s permit.

We have developed an application software to collect and statistically evaluate data, enabling us to get clear information about individual projects and their measurable characteristics directly from associated processes. The software determines whether the logged-in user is qualified for the project and has the necessary experience, completes it with the process and, according to the defined period, alerts the operator to the need to measure production and record data.